Tune-up process – Bacchus JT Series

Photos by Inokuchi Satoshi

Every JT (Japan Tune-up) Series model is set up to the same standards as the Aska workshop’s Made in Japan guitars, but available at a more affordable price. These guitars are made in our overseas workshops, but each piece is carefully inspected and adjusted in Japan. We believe that every player—whether a beginner or a professional—should have a guitar that is properly set up and ready to play.

The Deviser Technical Center, located next to our head office and the Aska Factory in Matsumoto, Nagano, is responsible for the tune-up process of the JT series. On this page, we show you how our skilled staff carefully set up each guitar.

Checking the individual condition

The first step is to check the guitar’s condition before setup. This includes not only looking for any damage to the body or neck, but also carefully inspecting each part that may need adjustments.

Once the inspection is complete, the neck is removed from the body to move on to the next step.

Fret leveling and polishing

After checking the neck condition, the frets are leveled to make sure each one is the same height, using a measuring scale. Right after leveling, the tops of the frets are flat, which can make playing feel uncomfortable. To fix this, the frets are carefully rounded and given a smooth curve on top.

Also, the fret edges are sanded and rounded so that your fingers don’t catch on them while playing. This process greatly improves playability. Finally, the fret surfaces are polished using sandpaper, steel wool, and a polishing cloth to give them a smooth, shiny finish.

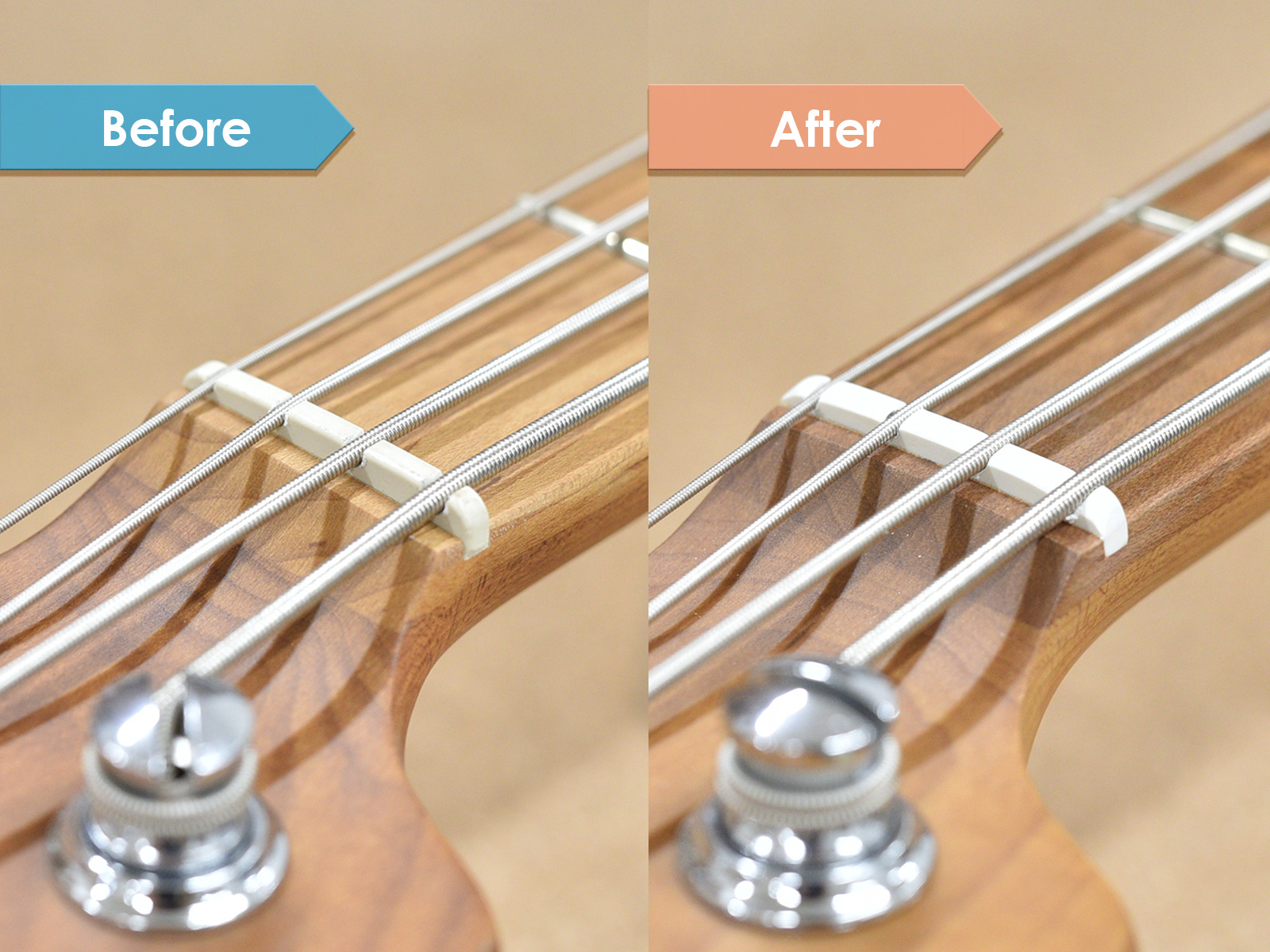

Rounding the nut

First, the nut is masked to protect it, then its edges are carefully rounded. This isn’t just for appearance, it also improves playability. When playing in the lower positions, the left hand can easily hit the nut’s edges, so making them as smooth as possible helps prevent discomfort.

Bridge Saddles and Pickup heights adjustment

Before reattaching the neck and body, adjust the saddle positions and pickup heights. This will make the following steps, such as setting the intonation, much easier.

Nut slot adjustment & other final finishes

After the strings are set, the height of the nut slots is carefully adjusted. Since the nut directly supports the strings and carries their vibrations, this is one of the most important steps in the setup process.

The luthiers sand, inspect by eye, and adjust the nut repeatedly to achieve the ideal string action and measurements, matching the same high standards as our Made in Japan line. This is a highly skilled task, done by hand, that cannot be replaced by a computer or robot.

Official seal and JT sticker

Finally, the sticker is applied as proof that the guitar is part of the JT Series.

The official seal is also placed on the back of the headstock, certifying that the instrument has passed quality control in Japan.

*Please note:

Since guitars are made of wood, the condition of the neck and frets may change after shipping, depending on storage conditions and humidity. Over time, regular use can also cause wear and affect the setup. That’s why regular maintenance is important. For example, changing strings is a good opportunity to check and adjust your guitar’s condition.