Pure Urushi lacquer sound – To truly enjoy the tonewood’s sound

Headway’s signature product is our Sakura, or Cherry blossom tree wood guitars. We pride in using unique Japanese wood materials from various regions of Japan and integrating techniques from traditional Japanese crafts into our guitars. We are constantly challenging ourselves to create guitars with the theme of “和”(Wa) which can be translated as meaning simply “Japan”, or “Japanese Style” that only a Japanese guitar maker can truly achieve. In this page, we will introduce you to a guitar made in conjunction with Mr. Kobayashi, a Urushi lacquer craftsman that works in the Asahi village, in Higashi-Chikuma-gun, Nagano prefecture.Headway’s philosophy One of our goals when making guitars is to make an instrument that can grow alongisde you throughout the decades as you yourself grow as a player. Slowly developing and getting better and better with time. To achieve this we implement a fusion of both traditional guitar-making techniques and our own innovations we have been developing for over 40 years.

Pure Urushi lacquer sound – To truly enjoy the tonewood’s sound

Headway’s signature product is our Sakura, or Cherry blossom tree wood guitars. We pride in using unique Japanese wood materials from various regions of Japan and integrating techniques from traditional Japanese crafts into our guitars. We are constantly challenging ourselves to create guitars with the theme of “和”(Wa) which can be translated as meaning simply “Japan”, or “Japanese Style” that only a Japanese guitar maker can truly achieve.

In this page, we will introduce you to a guitar made in conjuction with Mr. Kobayashi, a Urushi lacquer craftsman that works in the Asahi village, in Higashi-Chikuma-gun, Nagano prefecture. One of our goals when making guitars is to make an instrument that can grow alongisde you throughout the decades as you yourself grow as a player. Slowly developing and getting better and better with time. To achieve this we implement a fusion of both traditional guitar-making techniques and our own innovations we have been developing for over 40 years.

Japanese traditions and techniques passed down from generation to generation 『Headway』×『KOBAYASHI Lacquerware』

Profile

-Noboru Kobayashi

-Born in 1964, in the Nagano prefecture

-Associate member of Kokugakkai Crafts Division, member of Shinshu Wood Crafts Association.

-Started working professionaly with Urushi Laquer in 1981.

Produced original Urushi accessories, and provided Urushi lacquer finishes for many woodworkers and furniture makers.

-With his excellent lacquer painting skills and warm personality, he creates works full of unique Urushi charm to them.

Japanese traditions and techniques passed down from generation to generation 『Headway』×『KOBAYASHI Lacquerware』

Profile

-Noboru Kobayashi

-Born in 1964, in the Nagano prefecture

-Associate member of Kokugakkai Crafts Division, member of Shinshu Wood Crafts Association.

-Started working professionaly with Urushi Laquer in 1981.

Produced original Urushi accessories, and provided Urushi lacquer finishes for many woodworkers and furniture makers.

-With his excellent lacquer painting skills and warm personality, he creates works full of unique Urushi charm to them.

Features

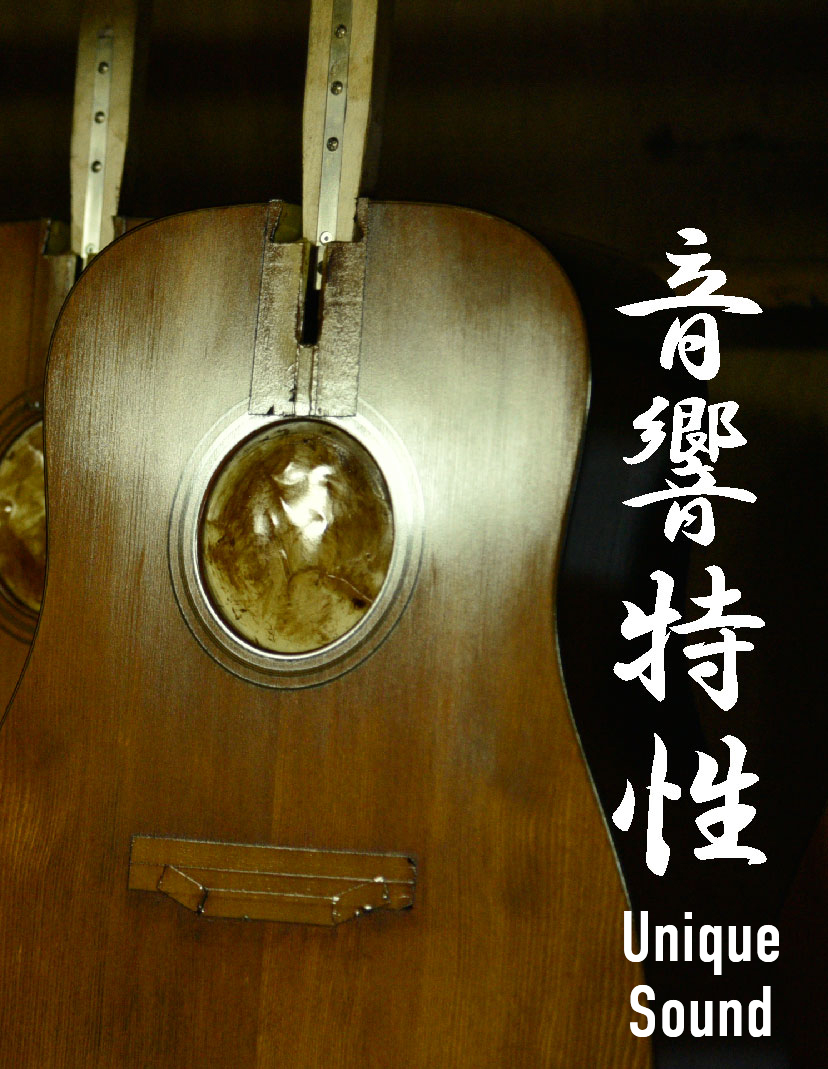

The utilization of Urushi in Japan is said to have started in the Jomon period (710-794). The making and utilization of Urushi lacquer is a traditional technique that has been loved by people since ancient times and has been handed down from generation to generation. So much so, that around the world lacquered items that utilize or resemble the aspect of Japanese Urushi lacquer are known as “japan”. Instruments lacquered with Urushi may seem unusual, but their strength and acoustic properties have long been highly regarded and prized in the world of classical instruments. We are often asked, “How would you describe the sound of a Urushi-laquered guitar? Unlike solvent-based paints, Urushi has a “fresh, pure sound that allows the qualities of the wood to shine through”.

Features

The utilization of Urushi in Japan is said to have started in the Jomon period (710-794). The making and utilization of Urushi lacquer is a traditional technique that has been loved by people since ancient times and has been handed down from generation to generation. So much so, that around the world lacquered items that utilize or resemble the aspect of Japanese Urushi lacquer are known as “japan”. Instruments lacquered with Urushi may seem unusual, but their strength and acoustic properties have long been highly regarded and prized in the world of classical instruments. We are often asked, “How would you describe the sound of a Urushi-laquered guitar? Unlike solvent-based paints, Urushi has a “fresh, pure sound that allows the qualities of the wood to shine through”.

Urushi lacquer has the slightly unusual characteristic of curing by the action of an enzyme, rather than drying by volatilization like solvent-based paints used for general painting. This enzyme is said to work best in an environment with a humidity of around 70 to 85% and a temperature of 24 to 28°C. After painting, each piece of lacquer is hand-painted under these optimal conditions and quality control is carried out by hand.

Urushi lacquer coatings are very thin, consisting of a layer with a thickness of approximately 0.05 mm. Although the thickness of about 0.05 mm may raise concerns about its durability, it adheres to the wood more firmly than solvent-based paints, resulting in a very solid finish. Urushi lacquer coating also has excellent antiseptic, waterproofing, and mothproofing effects, and it is said that “Urushi coating becomes most beautiful after a few decades”.

This guitar is a rare example of a guitar that allows you to feel the natural and pure sound of its materials, so much so that it can be called “the pure sound of Urushi lacquer” where you can taste the original freshness of the wood with your ears. While you can experience beautiful paintwork and changes in sound quality as the material blends with the regular lacquers, Urushi is the one and only technique that allows you to experience this in the most natural way.

Realease date: August 2022

Limited Product

HD-115 URUSHI SF, S/STD

Headway

HD-115 URUSHI SF, S/STD

MSRP・・・¥300,000(w/o Tax)

Realease date: August 2022

Limited Product

HF-415 URUSHI SF, S/STD

Headway

HF-415 URUSHI SF, S/STD

MSRP・・・¥300,000(w/o Tax)

Demo Video

Cautions

The best daily care is to wipe dry with a cloth. Be careful not to use polish or chemical cloths containing abrasives, as they can damage the lacquer film. If a slightly noticeable stain is found, we recommend wiping with a cloth tightly wrung out with water.

Urushi is said to have relatively low resistance to ultraviolet rays. What this means for this model is that the color will gradually fade over time, changing to a sligthly lighter hue. The darker colors that have entered the tiny crevasses in the wood grain will however remain, so there will be a stylish contrast that will arise.

Headway 45th Anniversary