The 115 and 415 are the classic models from the Showa era (1977 – 83), featuring traditional looks and Headway’s signature clear, grainy sound. The new “Extra Slim V” neck grip dramatically improves the playability while maintaining the traditional Headway characteristics and authentic specs.

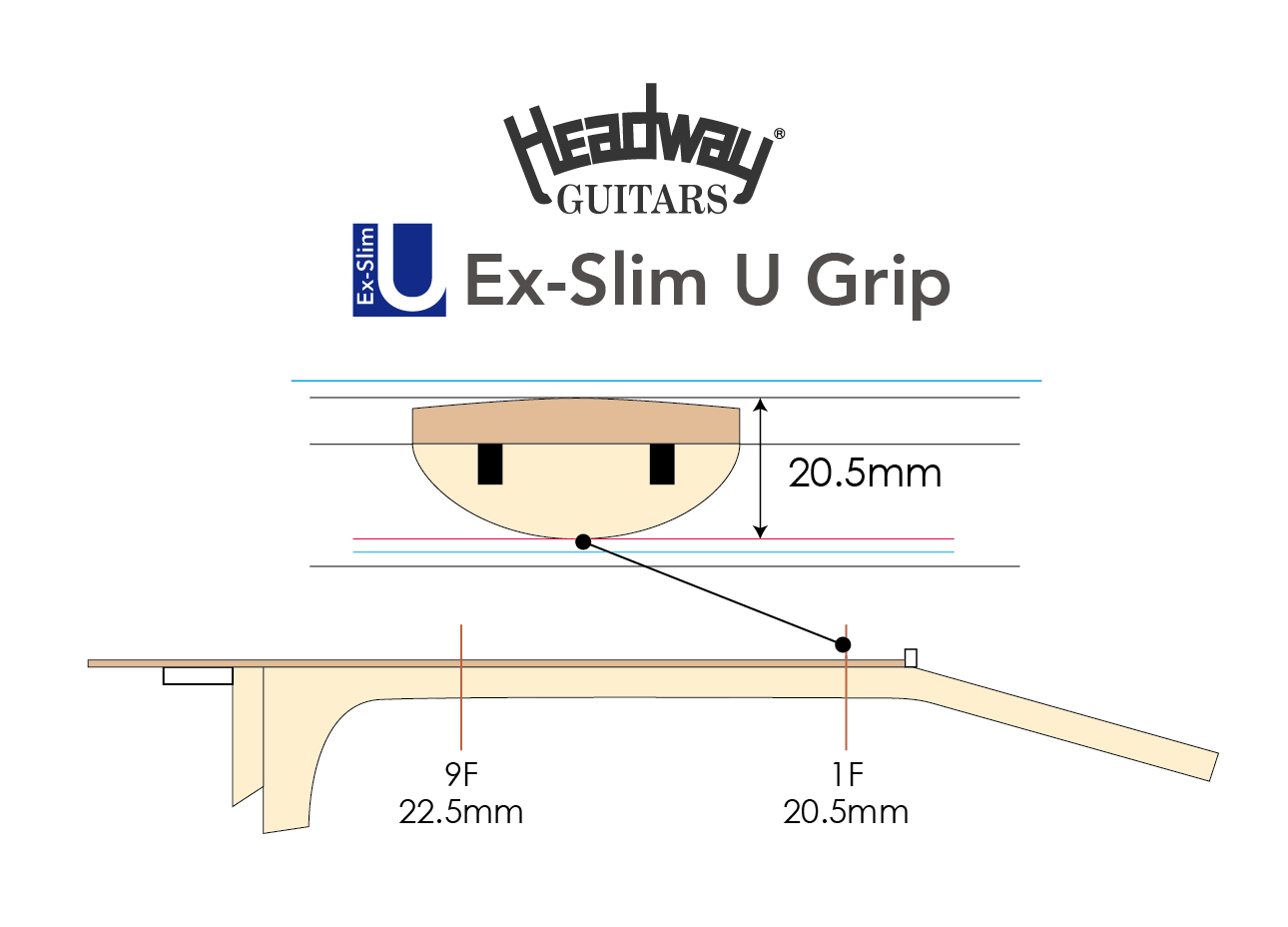

From left to right:HD-115 A,S-ESV/ATB、 HF-415 A,S-ESV/ATBThe 500 series was developed from the player’s perspective, with a sharp, modern look that produces a soft, expansive sound while maintaining the sturdy construction that is synonymous with Headway. The “Extra Slim U” neck is the thinnest neck in the history of Headway for high playability.

From left to right:HD-531 SF,S-ESU/ATB、 HF-531 SF,S-ESU/ATB

|

|

|

|---|---|

|

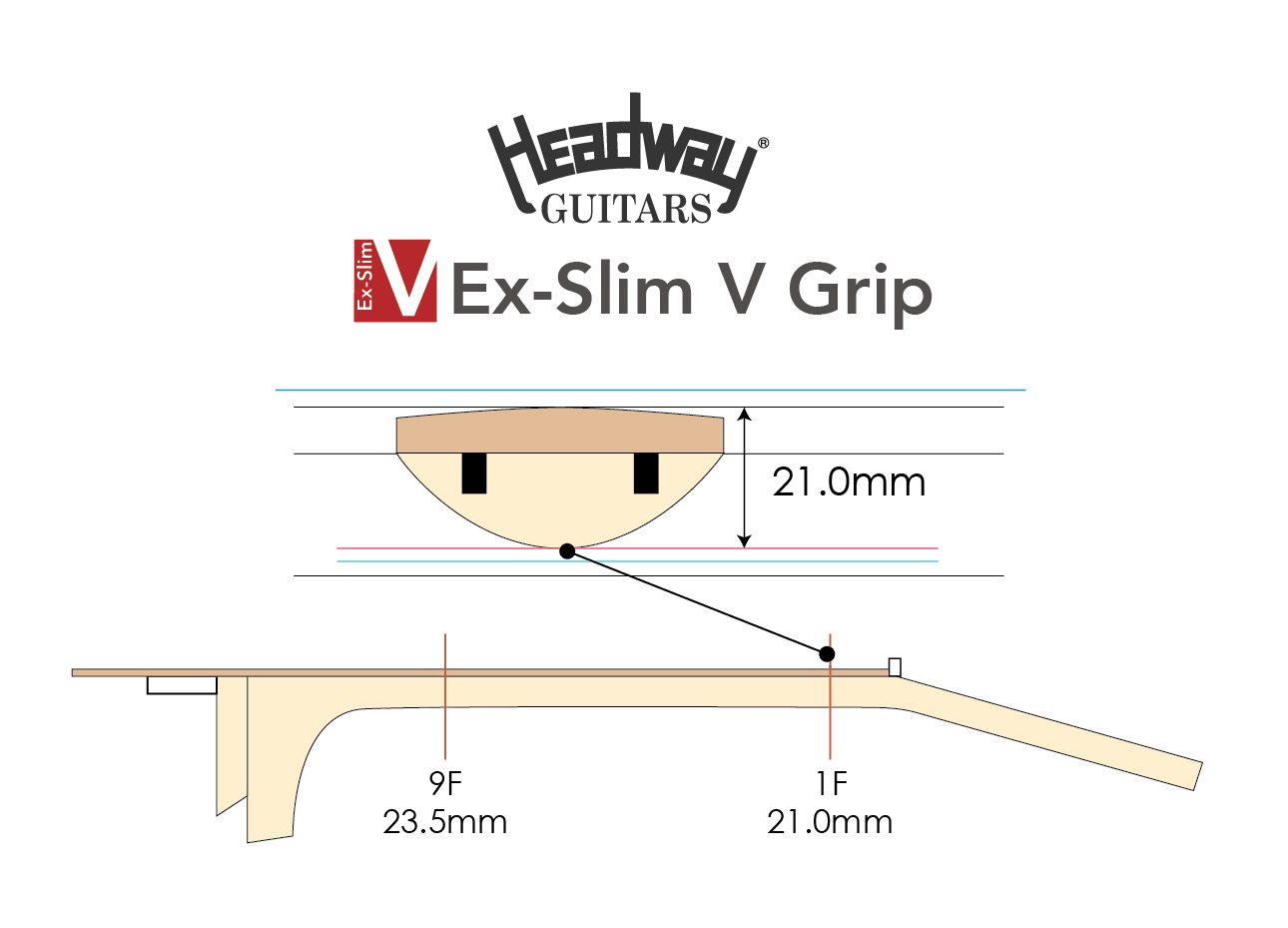

The top of the neck grip is a soft V shape with a slight point at the top. The sides are shaved to reduce the volume. It has a satin finish that feels smooth to the touch. |

It has a rounded shape that fits the curve of your hand like the letter U. The semi-glossy finish of the neck, like a neck that has been used for a while, provides a good grip that allows the hand to absorb the neck. |

|

|

|

|---|---|

|

The bracing cross position is set closer to the bridge side. It is characterized by a clear and bright sound with a strong core. Another advantage of this type of bracing is that it has a high reinforcing force, which reduces the risk of problems such as the bridge coming loose. |

The bracing cross is set closer to the soundhole. The wider open space near the bridge allows the top plate to vibrate more easily, resulting in a fuller, softer sound with more emphasis on the low end. |

|

|

|

|---|---|

|

A simple, traditional square headstock shape with a gothic logo that has been used since the company was founded. |

The headstock top features an inlay of a hawk flapping it’s wings. The logo is also designed to match the round shape of the head. |

|

|

|

|---|---|

|

The standard snowflake inlay that has been used since the first Showa 115 and 415. |

The size of the snowflake inlay changes depending on the size of the fret, making it even more gorgeous. |

|

|

|

|---|---|

|

A traditional three-ring design with black and white stripes. It is a universal design that fits any style. |

The herringbone pattern is accentuated by the addition of red lines, the theme color of the 500 series. |

|

|

|

|---|---|

|

Tortoiseshell pickguard with a traditional teardrop shape. |

Tortoiseshell pickguard in the original 500 series shape. |

|

|

|

|---|---|

|

The known belly type ebony bridge. This is a traditional style with a large area. |

Similar to the belly shape, but adjusted to a more modern shape by slightly narrowing the width and adding a curve. |

|

|

|

|---|---|

|

Roto-matic style machine heads, which cover the gears with a solid housing, are relatively heavier than the open-gear type and affect the sustain in the bass section. |

We selected the lightweight open-gear type pegs from GOTOH’s flagship 510 series. The light weight allows for greater expressiveness in the upper register, which is balanced by the strong 34 bracing in the lower register. |

While continuing the uncompromising Headway approach to guitar making that has been in place since the company’s inception, such as dovetailing the neck, great attention to detail, and using a one-piece neck, we continue to work on further improving the quality of our guitars by flexibly incorporating new materials and technologies.

One-piece Neck

The entire neck, from head to heel, is cut from a single piece of square wood.

This allows the entire neck to vibrate more easily and reduces the chance of problems naturally arising.

The entire neck, from head to heel, is cut from a single piece of square wood.

This allows the entire neck to vibrate more easily and reduces the chance of problems naturally arising.

All of Headway’s necks are one-piece necks, cut from a square piece of mahogany, of which only two pieces can be produced.

In this process, the middle of the block is basically rendered unusable.

Although there are more efficient ways to cut the wood, Headway custom builder Momose uses a one-piece neck because he believes in making guitars that can be used for a long time with peace of mind. In terms of sound, the wood fibers are not interrupted, resulting in a highly efficient transmission of vibration.

All of Headway’s necks are one-piece necks, cut from a square piece of mahogany, of which only two pieces can be produced.

In this process, the middle of the block is basically rendered unusable.

Although there are more efficient ways to cut the wood, Headway custom builder Momose uses a one-piece neck because he believes in making guitars that can be used for a long time with peace of mind. In terms of sound, the wood fibers are not interrupted, resulting in a highly efficient transmission of vibration.

▲Figure 1 Legend Top: Mahogany wood square Middle: Two necks cut out of mahogany Bottom: Loss of mahogany wood

Dovetail Joint

The neck and body are assembled with a dovetail joint.

Since the joint area is structurally larger, the transmission of vibrations is improved, contributing to better sound and a thicker sound core.

In addition, the Headway is processed very tightly so that there are no gaps at the joints, which further increases stability and prevents problems.

The neck and body are assembled with a dovetail joint.

Since the joint area is structurally larger, the transmission of vibrations is improved, contributing to better sound and a thicker sound core.

In addition, the Headway is processed very tightly so that there are no gaps at the joints, which further increases stability and prevents problems.

Post-coating neck joint

The neck and body are painted separately and then joined together after the painting process is complete.

The reason for using this method is to ensure that each piece is joined at the correct angle.

The thickness of the wood used for the body of an acoustic guitar is 2.5~3mm, and is greatly affected by external factors.

During the production process, the body is inevitably subjected to changes in lift and dents, and if the guitar is jointed beforehand, it is very difficult to make final adjustments, which can lead to problems later on.

In addition, it looks better when there are no paint puddles at the joint between the neck and body.

Since it is impossible to hide the joint with paint, this method requires a high level of precision to ensure that there are no gaps between the body and neck.

The neck and body are painted separately and then joined together after the painting process is complete.

The reason for using this method is to ensure that each piece is joined at the correct angle.

The thickness of the wood used for the body of an acoustic guitar is 2.5~3mm, and is greatly affected by external factors.

During the production process, the body is inevitably subjected to changes in lift and dents, and if the guitar is jointed beforehand, it is very difficult to make final adjustments, which can lead to problems later on.

In addition, it looks better when there are no paint puddles at the joint between the neck and body.

Since it is impossible to hide the joint with paint, this method requires a high level of precision to ensure that there are no gaps between the body and neck.

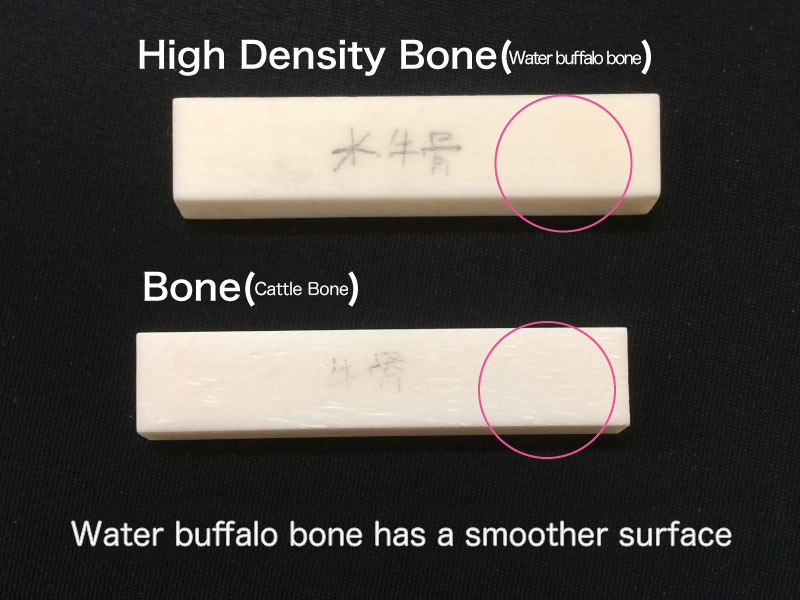

High-Density Bone Nut & Saddle

All models in the ATB series use Water buffalo bone (High-Density Bone), which has a higher bone density than regular cattle bone. We set strict standards at the procurement stage and use only those with a specific gravity of 1.7 or higher. This is close to the specific gravity of ivory, which is now very difficult to obtain and is highly effective in terms of sound quality as well as appearance and texture.

All models in the ATB series use Water buffalo bone (High-Density Bone), which has a higher bone density than regular cattle bone. We set strict standards at the procurement stage and use only those with a specific gravity of 1.7 or higher. This is close to the specific gravity of ivory, which is now very difficult to obtain and is highly effective in terms of sound quality as well as appearance and texture.

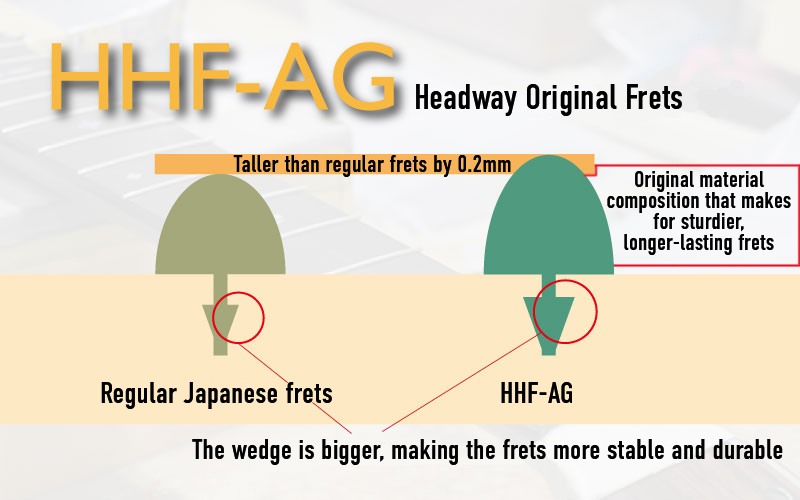

HeadwayOriginal Frets

All ATB series models use the original “HHF” frets, which are custom-made by a fret maker.

The material is nickel silver, but the hardness is increased by adjusting the ratio of the metal components, and the fret peaks are slightly higher (about 0.2mm) than the conventional frets to achieve a longer lifespan.

All ATB series models use the original “HHF” frets, which are custom-made by a fret maker.

The material is nickel silver, but the hardness is increased by adjusting the ratio of the metal components, and the fret peaks are slightly higher (about 0.2mm) than the conventional frets to achieve a longer lifespan.

There are other models with extra slim necks in the ATB series

Musicland KEY Shinsaibashi

Manager:Tomoya Fujita

First of all, the moment I played it, the way it sounded was totally different from the previous ATB500 series. While the 501 model with advanced rear shift bracing has the image of a big-boned sound with a strong bass range, the 531 model with 34’ bracing has a softer sound in the mid-low range, but the sound rises quickly. The nuance of picking is very easy to produce, and it can be used for all kinds of genres, but I personally recommend it for fingerstyle players. The “Extra Slim Neck,” which I experienced for the first time with this model, is also my personal favorite. It is very close to the neck of an electric guitar, and the position of the thumb is very comfortable when you hold it. I think it makes it easier to play technical phrases without feeling stressed. Also, the string height is adjusted low from the start, which is a great point. Up until now, Headways have had a slightly higher string height, and we’ve had a lot of customers ask us about that, but if you have that image, you’ll be surprised when you hold this model. If you have that image, this model will surprise you. This is a new model that is a perfect example of the Asuka Team Build (ATB) concept.

Tenri Gakki Co., Kashihara Main Store

Atsushi Shiroguchi

Actually, I personally prefer a thicker neck shape to some extent, but it feels so natural that I can enjoy this neck as if I didn’t have that preference. I can press the strings with ease even when voicing chords that require stretching, and I don’t get tired even after playing for a long time. The response to picking is very fast, and the guitar gives the impression of being a very expressive guitar, with sounds that can be played at the right time, from strong to gentle. It is not unnecessarily loud, however, and the attack sound is directly connected to the rich sustain, which gives a very pleasant feeling to play. Whether you play solo or chords, this is a versatile guitar that will suit any performance style and any performance scene!

Sumiya Gutti Main Store

Guitarist – Takashi Tsurui

The moment I played it, I thought “Wow! So easy to play!. It’s like my thoughts are directly transmitted to my fingers, and my fingers move on their own! To be honest, I thought it would be thinner, but it’s not too thick or too thin, it’s the ultimate perfect neck. I was also impressed by the fact that it was easy to play in any position.

Music Plant Tsukuba

Manager:Satoshi Ishii

Until now, I thought that one of the reasons for the HEADWAY sound was the firm and thick neck grip that is characteristic of STD and ATB. To be honest, this feature was also one of the reasons why it was difficult to recommend to some customers. In the past few years, there have been many cases where beginners, as well as intermediate and advanced players, have requested a thinner neck. I think this is due to the popularity of solo guitar and other playing styles. One of the advantages of having a real shop is that you can check the actual neck grip and see if it matches your playing style. As for the sound, I was personally most concerned about the glossy sound unique to HEADWAY with plain strings, but it was not lost. My impression of the HF-501 A,S-ESU/ATB that I actually touched was that it was tighter than the other HF types, and the fingerpicking rise was very musical. With more variations of neck grips, we can introduce domestic HEADWAY to more customers.

Music Miura

Representative: Kenichi Miura

I was very much looking forward to seeing the new neck grip guitar from Headway. I was worried that it would be a guitar with a very thin neck. I was worried that it might be a guitar with a very thin neck, but when I actually got to use it, it felt pretty great! Still, I could tell the difference right away! The grip on the neck remained almost the same even as I moved towards the higher frets. Normally, you feel the tension rising as you go to the higher frets, but I didn’t feel that at all with this new model! And above all, when I put on the capo tast, I can play with almost the same tension as if I were to go non-capo! It’s easy to play and the sound comes out great!

Ikebe Musical Instruments Store Acoustic Station Libore Akihabara

Haruomi Yasuhiro

The neck shape is easy to play with either a shake hand grip or a classical grip, making it suitable for all types of playing styles. The neck shape is easy to play with either a shake hand grip or a classical grip. The balance of the weight is also very comfortable. It is truly a stress-free neck.