Visiting our overseas workshops! (Headway &77 Japan Tune-up)

In this article, we’ll go into detail about Deviser’s overseas workshops and the products they manufacture!

We hope this article will help you you will feel closer to Deviser’s passion and dedication for our products.

Prologue: The Pride of Japan – The Quality of Aska Co., Ltd.

Aska Co., Ltd., is one of Japan’s leading guitar manufacturers, with its production base in Matsumoto City, Nagano Prefecture.

Thanks to our consistent product strength and quality over the decades, we have earned recognition not only in Japan but also from guitar players around the world.

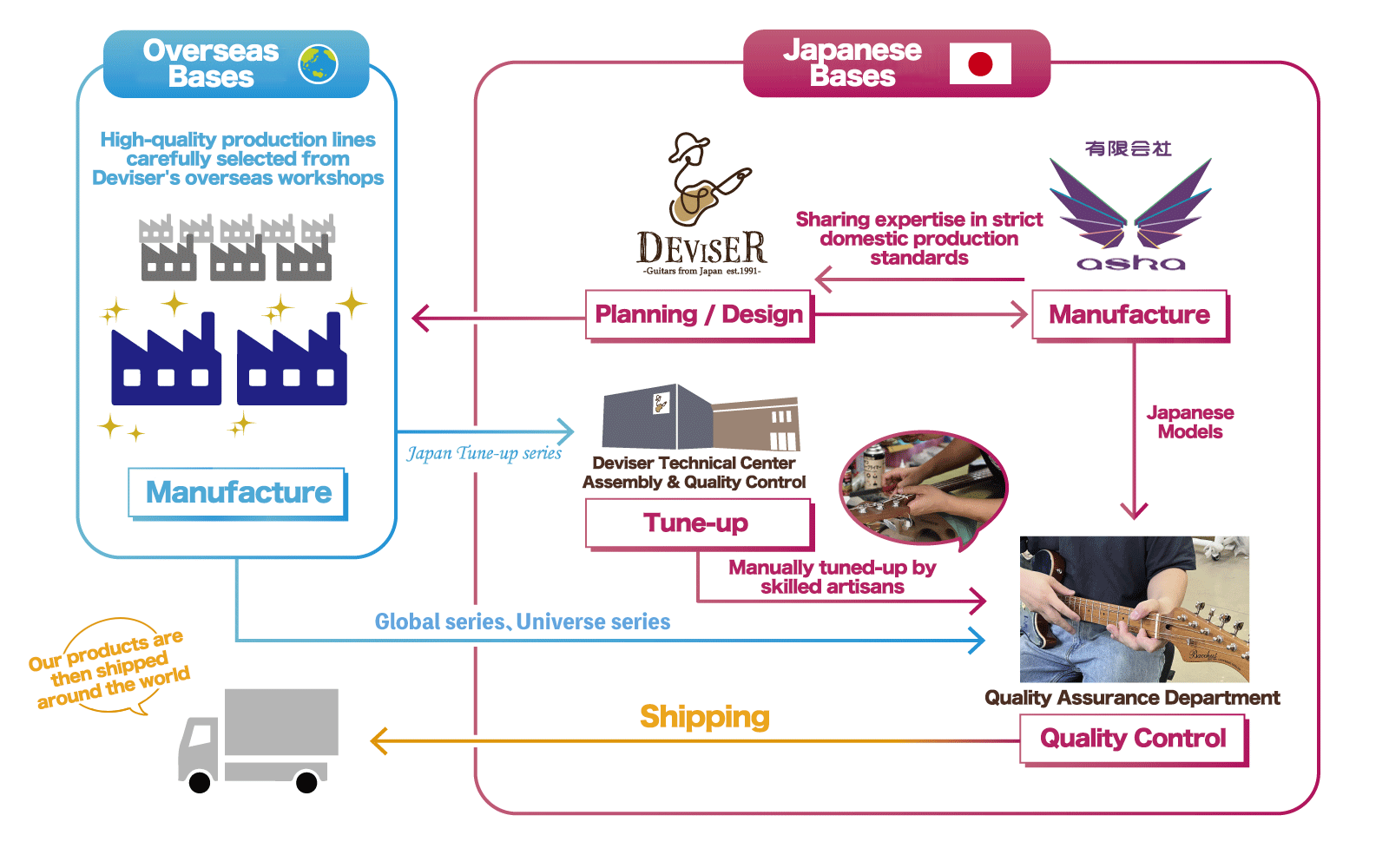

Deviser and Aska, both tracing their roots back to Headway Co., Ltd., founded in 1977, have worked together as group companies since their inception. Leveraging their respective strengths—Deviser handling planning and sales, Aska responsible for manufacturing and quality control—they continuously strive to deliver better products to the world through ongoing updates.

Deviser shares the quality improvement and guitar manufacturing expertise cultivated in Aska with its overseas workshops, striving to enhance quality.

Deviser’s pride – “Attention to detail”

Not only through collaboration with domestic companies like Aska and overseas workshops, but also through a core department that has been dedicated to quality improvement since Deviser’s founding.

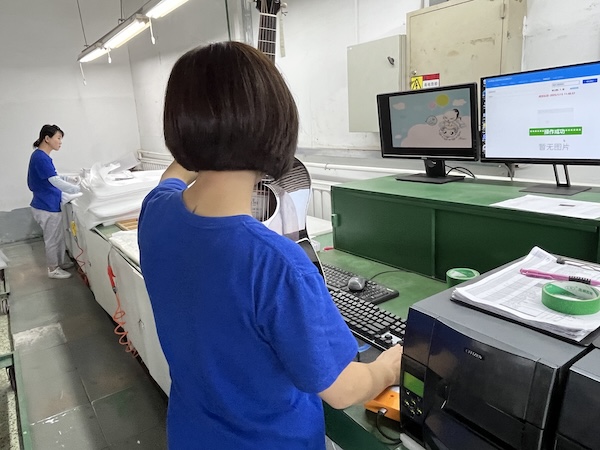

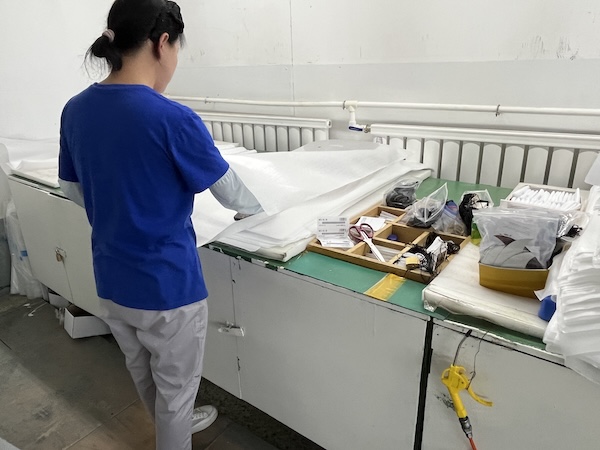

■Quality Control & Assembly Department

The Japan Tune-up Series is handled by a department staffed by specialized craftsmen. Our highly skilled team of artisans performs meticulous tuning down to the finest details, unlocking the instrument’s full potential in terms of playability and tonal expression.

■Product Quality Control Department

Our dedicated craftsmen inspect every single instrument arriving from overseas, not through random sampling but by examining each one individually, and set them up to ensure they are in proper condition.

The work performed in this department involves finding the optimal solution for each individual instrument, determining the ideal state for that specific unit, and adjusting it to achieve a playability and seasoned feel that surpasses its class, all the while maintaining its condition as a new and unused product.

By establishing a dedicated quality assurance department in addition to close collaboration with manufacturing plants, we can produce goods that still embody Deviser’s manufacturing spirit.

Products crafted with unwavering dedication are shipped to music stores worldwide and delivered to you, the player.

Now for the main topic: Regular visits to overseas workshops

Now that you’ve seen the process of bringing Deviser products to market, let’s finally get down to business.

Let’s take a look at some scenes from Deviser’s regular on-site visits to overseas workshops for new product development and quality improvement.

————————————————

The Deviser team takes a plane from Haneda Airport, and in a few hours, they arrive in mainland China. From there, they jump in a car and start their journey to the workshop.

Entering an alley revealed a row of restaurants facing the street, and after walking a short distance, it led to another alley connecting to a business district lined with buildings. During the day, it was bustling with heavy foot traffic, feeling more like an office district than an industrial zone.

A street where various roadside shops and restaurants line up, adjacent to a district with high-rise buildings, a cityscape where modernity and traditional China intersect.

After enjoying the cityscape, we will now take you inside Deviser’s overseas workshop in the next section.

There, local craftsmen were engaged in producing high-quality guitars of all sorts, incorporating handcrafted elements into their work.

First Look Inside Our Overseas Workshops!

This time, we visited the workshop where guitars for the Headway and SeventySeven brands’ Japan Tune-up series are manufactured.

This workshop features approximately ten manufacturing buildings spread across a vast site. Each section houses a separate production department, with numerous workers moving about.

In the lumber storage facility, uniformly cut lumber is stacked in layers and thoroughly seasoned to maximize its acoustic properties.

Here, taking the time to dry thoroughly is the first step toward crafting high-quality instruments with minimal likelihood of warping.

Hardwoods like rosewood and ebony, along with premium spruce essential for acoustic guitars, fill the warehouse to capacity. The finest grade materials are neatly displayed under strict management.

We manage our operations to ensure stable mass production of high-quality lumber.

The lumber is naturally air-dried for 2 to 5 years, then placed in a kiln to reduce the moisture content within the wood. First, the moisture content is reduced to 11-12%, and then gradually reduced over time to 6% before being sent to the manufacturing process.

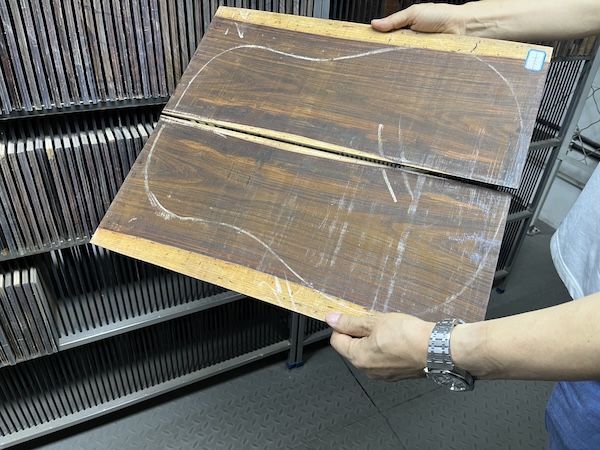

This is a storage facility where rare exotic woods and high-grade specialty materials are custom-cut and neatly displayed like bookshelves.

Seasoning periods and other details are indicated so that you can understand the specifics when using the product.

Some of these include rare and valuable wood materials, and even globally, few workshops manage such high-quality wood in such optimal conditions.

We were shown some deadstock Brazilian rosewood.

Due to import restrictions, commercialization is currently difficult, but the very existence of such rare materials speaks volumes about the variety of wood types and the richness of the inventory held by the workshop.

Then, after walking through the manufacturing process departments inside the workshop for several minutes…

The process of cutting spruce for the body tops and sapele for the body backs was underway, with inlays being filled.

Even just what’s visible in this photo shows a considerable number of body top pieces, but this is only a small portion; by the end of the day, over a hundred guitars’ worth of wood will be cut.

This is the process of wrapping binding around the spruce soundhole on the top plate.

Skilled craftsmen work with deft precision, and seeing them labor with such dedication makes one feel that the spirit of Japanese craftsmanship is truly shared.

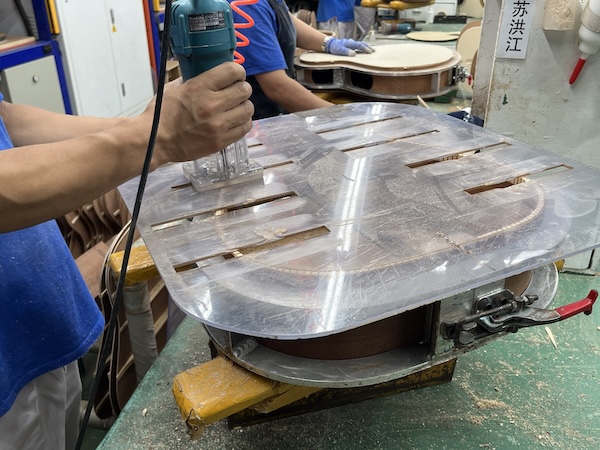

Next, we move on to the process of installing reinforcement material on the underside of the bridge on the body top.

We develop and use our own custom jigs and fixtures that can be adapted flexibly to accommodate the wide variety of guitar models we produce.

Within the factory, there are hundreds of items, including jigs and tools other than acoustic guitars.

This involves the body lining bonding process, thinning work, and center block adjustment work.

The center block, which connects the body and neck and significantly impacts both sound and strength, is carefully inspected and securely fixed in place.

The spruce top wood in the middle of processing is neatly organized.

Next is the neck gluing and sanding process.

The headstock veneer is also being applied, demonstrating high precision and streamlined efficiency in the work.

This workshop utilizes CNC routers for cutting and processing wood, advancing mechanization and efficiency. However, there are still numerous tasks requiring manual operation by skilled craftsmen, such as setup work and fine adjustments.

Work is performed accurately and meticulously based on the specified tolerance settings.

This task involves filling the side positions on the fingerboard.

It’s hard to convey in photos, but skilled craftsmen meticulously embed each piece by hand with precise, rhythmic speed. They hammer them in at a pace impossible for amateurs, and we found ourselves captivated watching them.

This step involves trimming burrs and rough edges from the lining inside the acoustic guitar. Thorough trimming here ensures a higher-quality, more polished instrument.

The craftsmen share a common understanding that a beautiful instrument directly translates to quality and tone, and their meticulous attention to detail is evident throughout.

Each unit is meticulously polished and finished by hand, one by one, by skilled artisans. While visiting, we sensed their strong determination to achieve a level of craftsmanship that rivals Japan’s own production processes. Every artisan works with the utmost care and precision.

The process of wrapping the body binding is handled by a veteran craftsman with decades of experience in this field, and the sheer speed is truly impressive. The work, performed with precision and speed, can truly be called craftsmanship.

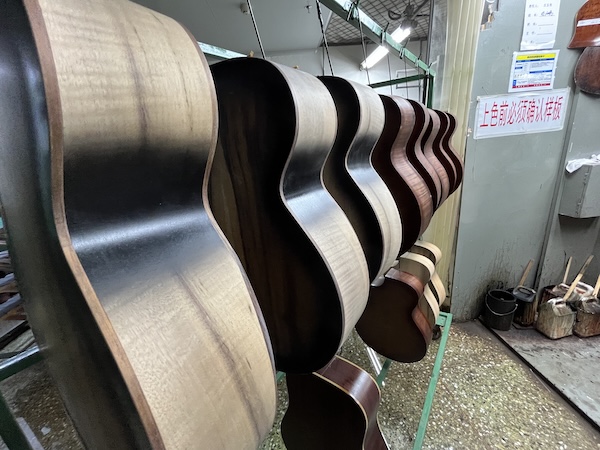

Body sizes also come in many varieties, including D-type and F-type, as well as cutaway types and the Florentine cutaway (HGAF) familiar from the Headway JT series, among others.

Generally speaking, when people hear “Asian workshop”, many still seem to have the impression that, compared to Japanese workshops, they prioritize mass production to such an extent that quality suffers.

However, there are also workshops where many experienced craftsmen are employed, and a system is in place to manage production and ensure high-quality products are made.

Further inside, neck grip machining was underway.

The necks with their familiar head shapes are lined up…

This machine processes multiple necks at once, yet each one receives meticulous adjustments to carve out the perfect grip.

This machine processes multiple necks at once, yet each one receives meticulous adjustments to carve out the perfect grip.

At first glance, it seems simple enough, but achieving uniform thickness and rolling it neatly requires skill.

Here is the finished SeventySeven Guitars neck.

The dovetail joint at the neck joint has also been meticulously carved out.

Each item is neatly displayed with its own management number to prevent model mix-ups.

If you’re familiar with Deviser products, can you tell which model it is from the image?

Correct! It’s the “Seventy Seven Guitars ALBATROSS-JAZZ-JT” released in 2025.

At that time, since it was still prior to the announcement, we were conducting an inspection visit that also served to check the manufacturing process.

The work was meticulously done without missing a spot, resulting in a very clean finish.

Many aspects demonstrate high-quality management comparable to domestic production in Japan, and as it possesses the highest quality among Deviser’s Asian production workshops, it currently operates as the production line for the Japan Tune-up series, which demands high quality even among overseas-made products.

In the paint booth, a popular model from Headway Japan’s Tune-up series, the HSJ-5150SE/A-FMY-C, was undergoing painting.

Achieving the right balance of light and dark in burst finishes, including the body sides, is challenging, and only a select group of talented craftsmen within the workshop undertake this work. While slight variations between individual instruments exist, the ability to produce a uniform burst finish is truly a testament to the skill of these master craftsmen.

Further inside, craftsmen were performing the painting work by hand.

Using specialized spray guns to gradually apply a burst finish that creates an elegant appearance, resulting in a meticulously crafted guitar of the highest quality.

Beside it stood some unfamiliar machine…

It was an arm-type painting robot, commonly seen in the automotive industry.

This workshop actively introduces new machinery throughout the year. Craftsmen handle delicate tasks that robots cannot perform, while robots handle tasks where efficiency is prioritized. Appropriate division of labor is implemented according to the nature of the work.

At another booth, there was a guitar with a faint cherry blossom tint that looked familiar.

This is the HOC-SAKURA/JS SPK-GRD from the Headway Japan Tune-up series.

They measure the coating thickness using specialized equipment. The standard thickness is 0.3mm, equivalent to the Aska Headway specification. Any coating falling outside the tolerance range undergoes regrinding or repainting.

We use a UV coating with high hardness that resists scratches. However, while it offers rigidity, if the coating becomes too thick, it hinders the wood’s ability to vibrate, compromising its resonance. Therefore, by meticulously controlling the thickness to maintain a thin coating, we achieve both protection for the guitar and excellent resonance.

And on the adjacent rack sits the HF-TSUKIMIYOZAKURA KWH-GRD, the Yome-chan Signature Model from “Yome to Ore”, freshly completed after its coloring process.

The KWH-GRD (Kagura White Gradation) color applied to the top surface has been beautifully finished.

The sunburst color on the Seventy Seven JT’s ALBATROSS-JAZZ-JT was also beautifully finished.

It seems they’re finally nearing completion.

The next step is the neck set process.

Headway has consistently employed one of its core manufacturing methods since its founding: the dovetail joint and post-processing assembly techniques.

Until now, replicating the “dovetail joint” and “post-processing assembly” processes at overseas production sites proved difficult, leading us to abandon these techniques. However, at this workshop, where we have built advanced technical capabilities, post-processing assembly has become possible for the first time. This has enabled us to follow Headway’s commitment to quality in the more affordable Headway Japan Tune-up series products.

“Post-processing assembly” refers to the technique of joining the body and neck together after they have been finished. This requires precise woodworking and advanced finishing skills. While painting after joining the body and neck would improve production efficiency, we still employ this labor-intensive post-processing assembly method primarily for the following two reasons:

1.The joint between the neck and body has no paint buildup, resulting in a clean finish.

2.By fine-tuning the joint angle between the neck and body prior to the post-processing assembly process, optimal playability can be achieved.

For more details, please also check out this video where Yometore explains it clearly and simply!

Skilled craftsmen perform multiple checks to ensure precise neck-to-body alignment, including neck angle adjustments, achieving uncompromising precision.

Here is the finished neck joint after final assembly.

The joint between the neck and body is not filled with paint or other materials; instead, it is precisely crafted to achieve such accuracy that the gap is barely visible to the naked eye.

The joint between the body and neck is a critical area for transmitting sound resonance.

Filling it with paint simplifies manufacturing control, but compromises the tone.

This extra step of meticulous care is a key element in creating the high-quality guitars Deviser strives for.

Finally, the neck set is completed by performing a thorough crimping process using specialized equipment.

Through these steps, a high-precision body is achieved.

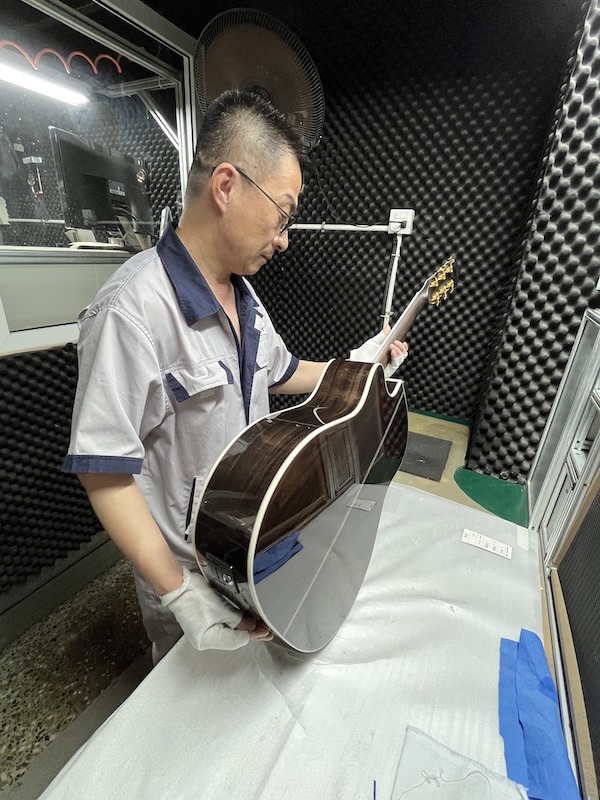

After that, we proceed to the inspection process for stringing, sound testing, and product checks.

Of course, we fine-tune each guitar’s settings through our Quality Control Department’s tuning process after arrival in Japan. However, even before shipment from Japan, every single guitar undergoes inspection, and any problematic units are corrected before being shipped.

—————————————————————-

That concludes our look at the production process at the workshop for the Headway and SeventySeven Guitars Japan Tune-up series!

Headway boasts the longest history among the Deviser brand’s lineup.

The Japan Tune-up series features a diverse range of distinctive models, including Sakura guitars and artist signature models.

However, developing distinctive products requires the essential quality of the guitar as an instrument.

It is precisely because this foundation is solid that we can create products that meet artists’ specifications and take on the challenge of new materials.

We hope this article on the production process behind the Headway and SeventySeven Japan Tune-up series products featured in this article has given you a glimpse into the secrets behind maintaining their quality.

Once these high-quality instruments are completed, they are finally shipped to Japan. After arriving at our bases, they undergo tuning and inspection by the Quality Assurance Department before being shipped to you, the user.

Epilogue: Applying Japan’s Premier Tuning Work to Overseas Guitars

News

Yometore, the official artists of Deviser, delve deep into the Japan Tune-up process!

Please give this video a watch!

Signature models

JT Tune-Up Feature Sites↓

Extras: Savoring the local scenery and cuisine

This workshop visit lasted about a week, and every night I feasted on the gourmet street just a 15-minute walk from the hotel!

Grabbing some cold ones with the gang,

Cheers!

The simmered fish was a bit plain, but it was fluffy and delicious. The spicy stir-fried water spinach also had that authentic local flavor.

We looked up that strange bamboo shoot-like thing after returning home, but we still don’t know what it is. If anyone knows, please let us know!

We’ve gone on a bit, but we’ll be bringing you regular updates on the day-to-day of Deviser regarding our workshops, so please look forward to them!!